| |

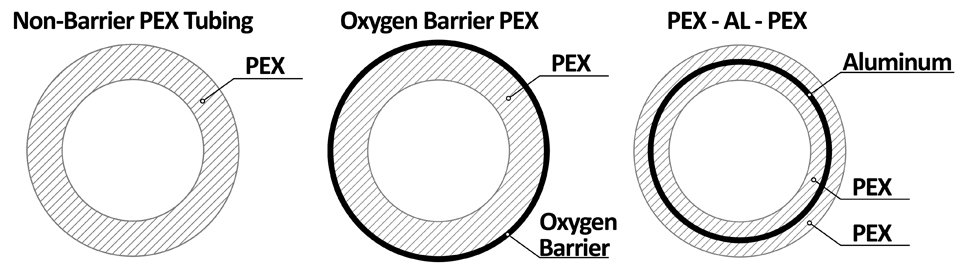

Non-Barrier PEX |

Oxygen Barrier PEX |

PEX-AL-PEX |

| Structural |

Plain extruded pipe with no external coatings or additional layers. |

External layer of EVOH polymer (glossy) which meets DIN 4726 standard for oxygen permeability. |

Internal layer of aluminum bonded to (2) layers of PEX. |

| Applications |

Hot and cold water plumbing. Open-loop hydronic heating systems. |

Closed-loop hydronic, radiant floor heating and snow melting systems. |

Coil memory

(tendency of pipe to return to original coil shape) |

Yes |

No |

| Connection systems |

Crimp, Clamp/Cinch and Push (Push-to-connect) methods |

Compression and press methods. |

Linear expansion

(inches per 100ft at 10°F temperature rise) |

1" – 2.5" |

0.3" |

| Weight per 100ft for 1/2" PEX |

~5.8 lbs |

~7.0 lbs |

| Pressure ratings |

160psi @ 73°F

100psi @ 180°F

79psi @ 200°F |

200 psi @73°F

160 psi @140°F

125 psi @ 180°F |

| Pricing |

Lowest |

Medium |

Highest |

Non-Barrier PEX overview

Flexible, economical and easy to install, non-barrier PEX tubing (a.k.a. PEX plumbing pipe) is a #1 alternative to copper and CPVC rigid piping for residential and commercial potable and non-potable water plumbing applications.

We carry this pipe in red and blue colors for easier distinction between hot and cold water lines and in all major sizes: 1/2", 3/4" and 1". Everhot PEX is NSF certified for potable water applications (including hot chlorinated water) and is lead-free compliant.

Oxygen Barrier PEX overview

External coating of oxygen barrier PEX tubing effectively prevents diffusion of oxygen molecules into the water through walls of the pipe. This feature prevents corrosion of cast iron components in the system (circulator pumps, air purgers, fill valves, boiler heating elements, etc.) and allows using it in hot water hydronic heating applications, including baseboard/radiator heating, fan coils, radiant floor heating and snow melting applications.

Available in all major sizes (3/8", 1/2", 5/8", 3/4" and 1") and coil lengths ranging from 100ft to 1,000ft.

PEX-AL-PEX overview

The main and most distinctive feature of PEX-AL(Aluminum)-PEX is the internal layer of aluminum, "sandwiched" between two layers of PEX. This layer adds memory feature to the tubing and allows it to retain the shape to which it was bent. Memory feature is very useful in all PEX project types and allows for a 1-person installation. Aluminum layer also provides an oxygen diffusion barrier with no need for additional coatings. Pressure ratings of PEX-AL-PEX are also higher than that of the regular PEX.

Available in 1/2", 3/4" and 1" sizes and 300-1,000ft coil lengths. Orange color.

Related resources:

Comparison of PEX tubing by manufacturing type (A, B, C).

Technical specifications of barrier and non-barrier PEX.