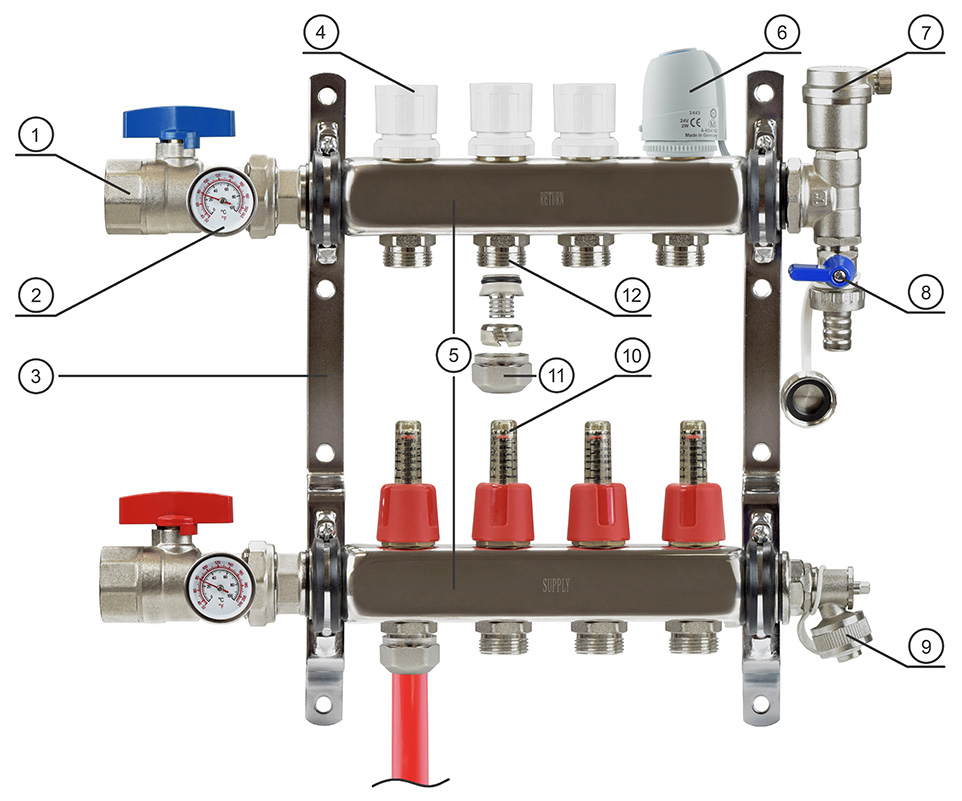

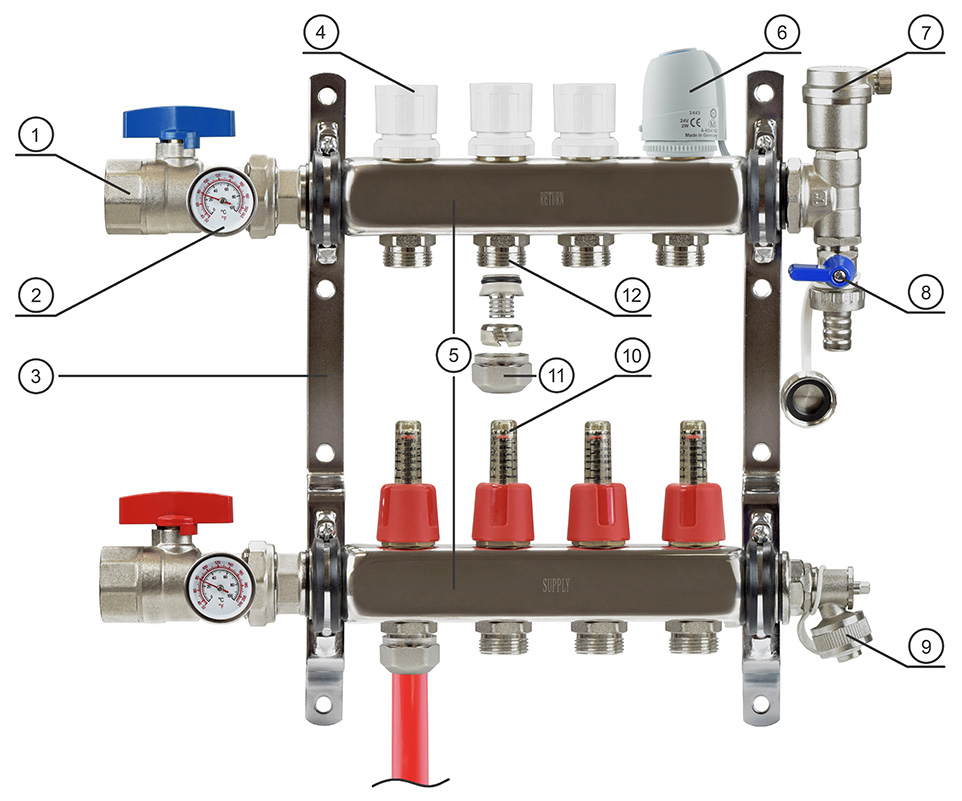

1. Shut-Off Ball Valves

1. Shut-Off Ball Valves

(2) Shut-off ball valves are included in each manifold set. Shut-off valve has a large 1/4-turn handle, a 1" NPT (U.S. standard) female threaded inlet connection and a 1" outlet connection. Valve also has a union which allows to disconnect it from the manifold for maintenance or repair purposes.

2. Temperature Gauges

A large, well-type, replaceable gauge with temperature range 32-210°F (0-100°C). Gauges on both supply and return lines help determine the ΔT° temperature differential and to adjust the system’s settings as needed.

3. Support Brackets

Support bracket set has (8) holes for securing the manifold set to studs or to a wall and provides an offset for the lower manifold so as to allow the

PEX tubing lines from the upper manifold to pass behind it. Clamps which hold individual manifold (supply or return) in place have rubber pads which also provide dielectric insulation.

4. Manual Balancing Valves

Balancing valves are used to regulate the flow through individual branches of the manifold.

Since PEX tubing circuits are not always of the same length, shorter loops will deliver the heat faster, while longer ones will take more time. Balancing valves, in combination with flow meters, help to solve this problem by means of adjusting the flow through individual PEX loops, so that a desired temperature balance can be achieved.

Unless length of PEX loops varies by more than 10%, all of the valves can remain in the fully open position, with no adjustments required.

5. Supply/Return Manifolds

(1) Supply (lower) and (1) Return (upper) manifolds in either stainless steel (SSM models) or brass (BSM models) body. The default recommended installation is shown on the main picture, with air vent installed on the top manifold (return).

6. Actuator/Zone Valve (Optional, not included)

Actuators replace manual balancing valves to achieve automatic zone control. They can be used to split the manifold into "zones" where each zone (room or area) can be controlled by one or more actuators, which, in turn, are controlled by a thermostat located in this zone. Actuators are used in combination with zone control modules, such as the

Taco ZVC series and 24V

thermostats.

7. Automatic Air Vent

Air vent continuously eliminates larger size air bubbles from the heating system. By default, it should be installed at the top manifold (return), where the air accumulates.

8. Main Drain Valve

Drain valve with 1/4-turn handle and an outlet cap. Unless the system has an

automatic feeding valve installed, this drain valve can be used for filling the system with water or for draining the system for purposes such as maintenance. The air vent directly over the valve helps to eliminate a large portion of the air which enters the manifold during the initial filling of the system.

9. Secondary Drain Valve

Another drain valve for air purging or filling of the system.

10. Flow Meters

Flow meters (installed on the supply manifold) indicate water flow through individual manifold branches. Maximum allowed flow through a single branch is at 1.4 GPM.

Flow meters can also act as secondary valves and may be used to reduce the hot water flow by screwing the flow meter clockwise (viewed from top) or increase the flow by unscrewing it. This can be done by removing the red cap and making necessary adjustments by hand. By default, all flow meters are unscrewed to allow for maximum flow. A steel retainer ring prevents the meter from popping out of the manifold under pressure, while lubricated O-ring effectively prevents leaks.

11. Compression PEX Fittings (Adapters/Connectors)

Fittings which connect PEX tubing to the manifold are included in each set. Default size is for 1/2" PEX, alternative sizes (3/8", 5/8" PEX or 1/2" PEX-AL-PEX) can be requested at checkout at no additional cost. Each fitting is comprised of a PEX insert, compression ring and compression nut. This assembly connects PEX pipe to the manifold with a help of a standard adjustable wrench.

12. Manifold Outlets

Universal outlets can accommodate all PEX adapter sizes, with no need for an intermediate connection.

To browse our extensive selection of radiant heat manifolds and parts,

click here.